Strong, durable and easy to install wall coverings in Canada and the northeastern United States.

The Luxor Architectural wall covering is made of extruded aluminum type 6063-T5.

The T5 class of extruded aluminum 6063 offers the ideal properties for architectural wall coverings: a tensile strength of at least 140 MPA, with a dimensional stability equal to or less than 0,30% based on recognized North American outdoor temperatures, increased impact resistance, non-combustible and compliant with ULC-S135.

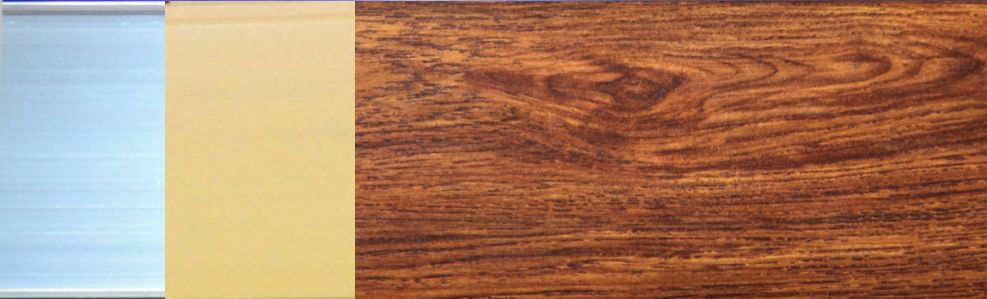

Natural wood-like wall coverings

Luxor is indeed a proud pioneer in the manufacture of wall coverings. The aesthetic finishing of surfaces by sublimation of our wall coverings is a process that has proven itself for more than 40 years in other sectors of activity. This method makes it possible to reproduce the desired effect of natural wood with wood grains and its typical shades of colours.

Once installed, our architectural products do not require any maintenance effort, unlike wood and other derivatives. No need to repaint them, they won’t crack or decompose over time.

The aesthetic finish of the exposed surfaces of our wall covering boards and their mouldings consists of a pre-treatment meeting the AAMA2605 standards and an ecological electrostatic powder paint texture in polyurethane, avoiding the flaking of paint due to the oxidation of aluminum and allowing our architectural products an increased resistance against discolouration and scratches as well as exceptional flexibility to deformation.